Residual tensile stress from welding

is created because the weld consumable is applied in its molten state. This is

its hottest, most expanded state. It then bonds to the base material,

which is much cooler. The weld cools rapidly and attempts to shrink during

the cooling. Because it has already bonded to the cooler and stronger base

material, the weld is unable to shrink. The net result is a weld that is,

essentially, "stretched" by the base material causing a tensile stress

condition.

The heat affected zone is usually most affected by the residual stress and hence

where failure will usually occur. Inconsistency in the weld filler material,

metal chemistry, weld geometry, porosity, etc..., act as stress risers for the

residual and applied tensile stress to initiate die fatigue failure. As

shown below,

MetaLL

ifeÒ

is extremely beneficial in reversing the residual stress from welding that tends

to cause failure. These stresses in the die cast tool's heat affected zone are

converted to a beneficial compressive state.

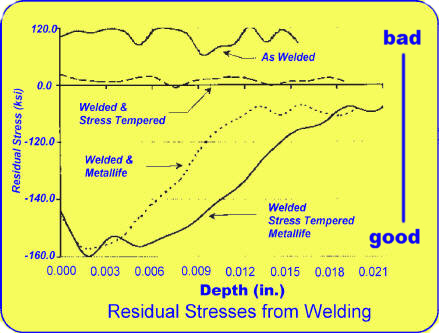

The below graph demonstrates a number of interesting changes in residual stress

from welding, thermal stress relieving and from

MetaLL

ifeÒ.

Tensile stresses generated from welding are additive with applied load stresses.

This is why these combined stresses accelerate failure at welded locations.

Heat stress tempering to reduce the tensile to zero (approximate) then following

with

MetaLL

ifeÒ,

restores the integrity of the weld and its relationship with the base material.

|