| |

|

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

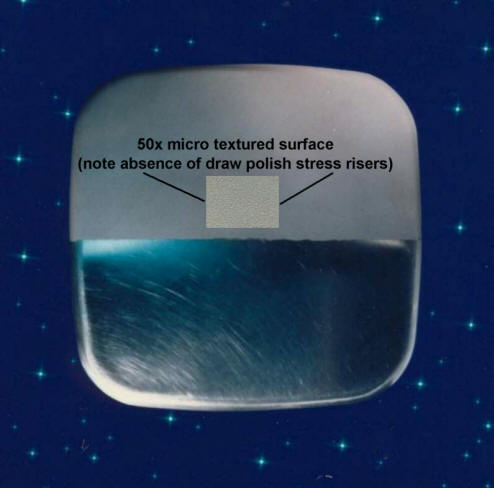

compressive stress finish vs draw polish stress risers

Draw polish creates stress risers that

lead to heat checking and cracking

Draw polishing has been used for decades to help with the

release of castings and to help the aluminum alloy to flow better over flat

surfaces. What wasn't understood, however, was the effect the stoning

(cutting edges) is having on the surface of the steel. The fact is, draw

polishing acutely cuts stress risers into the casting surface of the steel.

These stress risers often lead to aiding the start of the most frustrating

issue a die caster has with tool life...heat checking, cracking, and

possible cavitation breakout in certain affected areas.

|

|

|

|

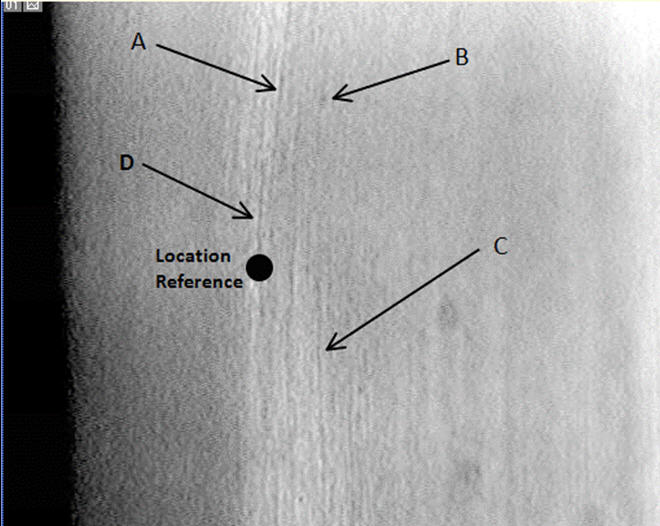

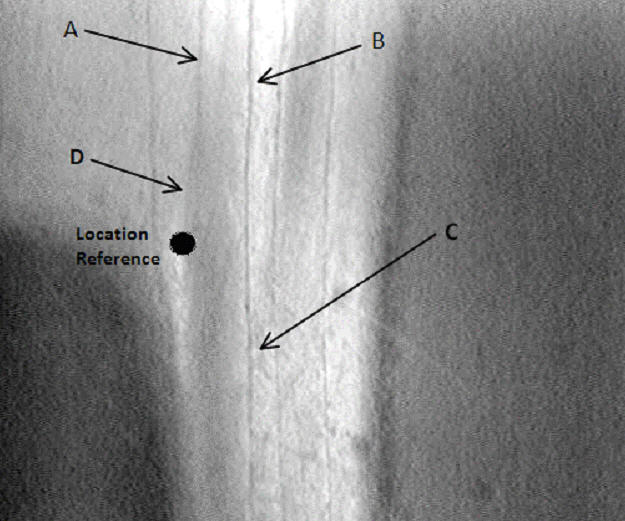

Draw Polish Stress Risers Shorten Die

Casting Tooling Life

stoning marks on die finish

Draw polish marks create stress risers

migrate into cracks,

heat checks, and breakout

through the life of the tool

|

|

|