Automated Measurement System for Gas

Nitriding and Nitrocarburizing

Vytas

Braziunas, Automation Intelligence LLC, Milwaukee, Wis., Leo Porkka,

Metallurgist, Milwaukee, Wis., and Daniel H. Herring, The HERRING GROUP,

Inc., Elmhurst, Ill.

Measurement of the ammonia dissociation allows for

an improved understanding of nitriding and nitrocarburizing processes,

as well as process repeatability and precise parameter adjustment. A new

advanced control system allows optimization of gas use and case

microstructure.

|

|

click on above

table for printable view |

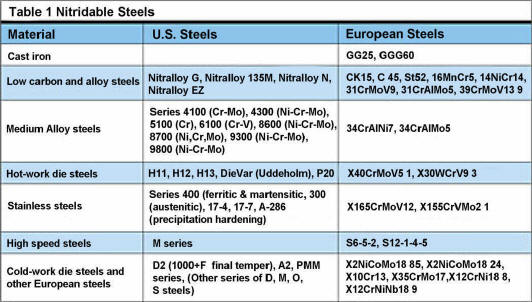

Nitriding and nitrocarburizing are surface

treatements intended to

increase surface hardness and to improve other properties of tool steels such

as those listed in Table 1. One of the appealing attributes of this

thermo chemical ferritic nitrocarburizing (FNC)

process is that rapid quenching is not required; hence, dimensional

changes are kept to a minimum. Nitriding and nitrocarburizing benefits

include:

- Ability to streamline the manufacturing cycle by eliminating

processing steps.

- Exceptionally high surface hardness

- Resistance to wear, anti-galling properties (good in poor

lubricating conditions), and the reduction of soldering tendencies in

die cast and aluminum extruding operations.

- Minimal distortion and deformation compared with

carburizing/hardening

- Resistance to tempering; resistant to softening up to nitriding

temperature at which conventional steels soften

- Stable nitrided case

- Improved fatigue life and other fatigue-related properties such as

fatigue strength (resistance to dynamic loading)

- Reduction in notch sensitivity

- Marked resistance to corrosion in several common media (except for

nitrided stainless steels)

- Small volumetric changes (some growth does occur)

|

| Fig 1. Modern gas nitrocarburizing furnace |

Nitriding and nitrocarburizing surface treatments have been used

increasingly over the past decade. Non-gaseous processing methods, such

as salt and plasma nitriding, have not reduced the interest in gaseous

nitriding/nitrocarburizing, primarily due to the flexibility in

processing parameters, which allows achieving an optimized

microstructure to meet treated component application requirements. These

one-step processes are replacing two- or three-step conventional

processes, such as carburizing or carbonitriding followed by grinding

and/or plating, due to benefits such as minimal dimensional change and

high surface hardness. However, there are currently a substantial number

of furnaces in use that do not have adequate process measurement and

control systems, which are required to meet the demands of today's

customers.

Innovative commercial heat treat companies are

improving furnace atmosphere control by adapting state-of-the-art

temperature and atmosphere controls, which provide continuous, precise

regulation of the process in progress (Fig.1).

|

| Fig 2. Automatic nitriding potential

measurement system |

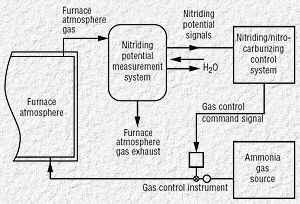

Three major benefits of control systems based on automatic nitriding

potential measurement compared with traditional open-loop furnace

control, where predetermined amount of gas is pumped into the furnace

over certain amount of time are:

-

Reliable measurement of nitriding potential, which enables a

repeatable process and prevents the degradation of processed part

quality caused by hard to control circumstances, such as failing

seals

-

Automatic control, which offers the ability to use just the right

amount of gasses, lowers the processing cost and minimizes

emissions

-

Optimal nitriding potential level, which allows processed parts to

meet case specifications and controls the growth of the white

layer

Limitations of existing control

methods

|

| Fig 3. Nitriding potential measurement system

block diagram |

Several methods of automated measurement of nitriding potential or

ammonia (NH3) dissociation percentage in a heat-treat atmosphere are

being used, usually consisting of photometry of ammonia in the infrared

range while ammonia is still in gaseous form. The principal of infrared

photometry is based on measuring the intensity of infrared light

transmitted, absorbed or reflected from a gas sample and comparing the

results with a reference light intensity. Disadvantages of this type of

process include interference of other gases in the mixture, drift of the

instrument, the need for frequent calibration and expensive span gas.

One of the biggest obstacles of using infrared nitriding potential

measurement in the heat-treat production environment is the necessity to

have extremely rigorous maintenance procedures in place to keep the

optics and sensors clean.

|

| Fig 4. Nitriding control system with multiple

sensors diagram |

Another automatic nitriding-potential measurement method involves

determining the individual gas concentration in a mixture of gases by a

thermal reaction heat measurement, where the heat is generated by

ammonia being burned on a catalyst. This approach is also difficult to

perform reliably in an industrial setting.

Another method involves determining the concentration of gases that

are a product of dissociated ammonia (such as hydrogen) and calculating

actual dissociation. This approach also uses sensors that can drift,

which gives false readings, and that are not always able to endure the

harsh furnace environment.

One of the most widely used nitriding potential measurement of the

gas mixture is a manual sampling method. This is performed by capturing

a predetermined amount of gas in a special ammonia dissociation

measurement burette, then dissolving ammonia in the gas form into a

liquid form, and determining the concentration of ammonia in solution by

visually measuring the level of water. Problems with this measurement

method are fragile equipment, difficult visual extrapolation and

interpretation of the water level measurement, which make manual burette

measurements challenging to use in an industrial setting, but it remains

a measurement of choice for a wide variety of furnace operators.

New automatic measurement

system

|

|

|

Tool Steel Examples

Fig 5. Left - Hot-worked

H-13 die casting die

Middle - Hot worked H-13

aluminum extruding die

Right - M2

punches |

A new automatic nitriding-potential measurement system (Fig. 2) based

on dissolving ammonia in water has been designed to improve existing

furnace controls. The system is installed and operating at a commercial

heat treating company in Milwaukee, Wisconsin. In

addition to sensing nitriding potential, the system also generates

process alarms and provides closed-loop ammonia control within the

heat-treating furnace.

System description and operation

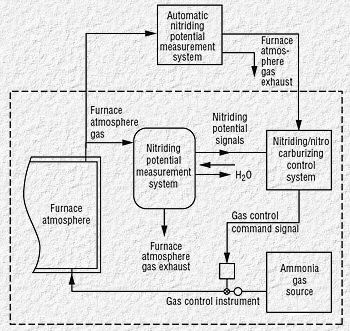

Increasing process-quality challenges require operator-friendly

measurement devices, which removes operator-induced variability, while

requiring minimal maintenance. The automatic system (Fig. 3) performs

the measurement and allows the operator to adjust process variables

manually or automatically according to a pre-set program.

The system-engineering goal was to design a robust,

stable system that could survive harsh plant environments, while

providing continuous, accurate and easy-to-define process measurement.

The high accuracy and repeatability requirements of processes

presented even greater challenges.

The nitriding potential-measurement system is set-up to automatically

sample the furnace atmosphere. The main measurement chamber is equipped

to receive the true processing atmosphere that exists in the

nitriding/nitrocarburizing furnace. The measurement chamber is also

equipped with water inlet and outlet lines and atmosphere exhaust line.

Water for precision measurement is supplied from a specially designed

constant low-pressure water vessel. The water is used to process furnace

atmosphere gas samples and to calculate the nitriding potential. During

the measurement cycle, the water flow and volume required for full

ammonia dissolution is measured using electronic sensors, which generate

signals that are converted by a digital controller into process

information. The measurement result is automatically logged and

instantaneously reported to a furnace operator. The information can be

presented in multiple formats, such as nitriding potential, percent

residual and percent dissociated ammonia.

Nitriding-potential information is sent to the

nitriding/nitrocarburizing control system, which allows adjustment of

gases flowing in the furnace based on the input. An automatic

self-calibration procedure is a unique characteristic of the system,

which is especially critical when processing expensive workloads.

Automatic self-calibration can be performed according to a pre-set

schedule, or initiated by the operator as needed, does not require

certified gases and is based on a precise measurement of the known

vessel volume.

|

Fig 6

|

|

Fig 7

|

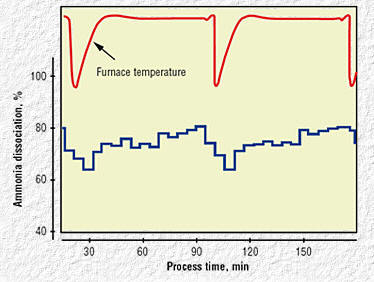

Fig 6. Process temperature and ammonia

dissociation measurement example

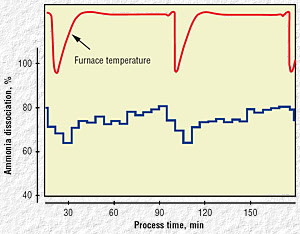

Fig 7. Excess ammonia

supply |

Multiple sensors increase reliability

Automatic nitriding-potential measurement offers the use of multiple

sensors to augment existing sampling or in-situ systems for increased

accuracy and control reliability. This aspect of the nitriding-potential

measurement determined using the new automatic gas dissolution in water

method is comparable to ammonia measurement results achieved using other

measurement methods.

This combination system with redundant capability (Fig. 4) offers

high reliability and continuous availability compared with a single

sensor control system. Sensing deviation from other sampling or in situ

automatic systems can be also minimized by using the multisensor

system's self-calibration feature.

The new measurement system is suitable for use with integral quench

furnaces, fluidized bed furnaces, pit furnaces and retort furnaces, and

can be used to monitor and control ammonia dissociator performance.

Process gas-sampling frequency is adjustable and can be set up by the

operator to achieve optimal control over the full processing cycle.

Process measurement and control

examples

|

| Fig 8. Controlled ammonia dissociation

process chart |

Commonly nitrided and nitrocarburized part include

components made of plain or medium carbon, low -alloy steels used in

automotive, agricultural, hand tool, lawn and garden and medical

applications. Other uses in the tooling area include hot work and cold work tool steels for applications in die

casting, drawing/forming/blanking, and aluminum extruding dies. Fig. 5

shows applications for die casting, aluminum extrusion, and heading

punches.

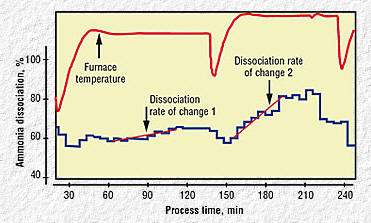

To establish a baseline of the processes being measured and

controlled, a number of tests were performed in a batch furnace using

the new ammonia measurement and control system. Furnace temperature and

ammonia dissociation information (Fig. 6) were recorded for two process

cycles. The ammonia flow in the furnace was kept constant, while the

temperature was set at two different and subsequent higher temperatures

during the first and second cycle times.

|

|

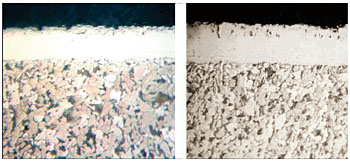

Fig 9 -

Microstructure of part processed using constant ammonia flow method,

left, and microstructure of part processed using reduced ammonia

flow, right. |

Tests were performed (Fig. 8) to determine the optimal amount of

ammonia to produce the desired processed part characteristics. When the

dissociation of ammonia is decreasing, the possibility exists that

excess ammonia gas is being supplied to the furnace. Control of gas flow

in this case will allow realizing a substantial gas savings.

Flow control can be implemented after understanding the process

dynamics. Part configuration and surface area must be taken into

consideration when selecting the control algorithms. For the two loads

made of the same material and processed at the same temperature, the

load with the larger surface area will tend to reduce nitrogen activity

more rapidly, as more ammonia molecules dissociate at the larger steel

surface area per unit of time. Figure 8 shows a chart of the controlled

ammonia dissociation during two consecutive batch processing cycles. The

microstructure of the part processed using the common industry method of constant ammonia

gas flow method

is shown on the left side of Fig.9 and that of the part processed using

reduced ammonia flow by the control method is shown on the right side of Fig.

9.

References

1 Principles of

Nitriding and Nitrocarburizing, Atmosphere Heat Treating, Basic Seminar,

Ipsen International, 1998

2 T.G. Diggs, S.J.

Rosenberg and G.W. Geil, Heat Treatment and Properties of Iron and

Steel, NBS, Monograph 88, 1966

3 E.Z. Lehrer,

Elektrochem, V61.36, No.6, p 383-392, 1930

4 K.H. Jack,

Nitriding, Heat Treatment '73, The Metals Society, Book 163, p 39-50,

1975

5 T. Bell, et.al., Controlled Nitriding in

Ammonia-Hydrogen Mixtures. Heat Treatment '73, The Metals Society, Book

163, p 51-58, 1975

6 B.J. Lightfoot and

D.H. Jack, Kinetics of Nitriding with and without White Layer Formation,

Heat Treatment '73, The Metals Society, Book 163, p 59-65, 1975

7 S. Mirdha, Ph.D. Thesis, Univ. of Leeds, 1980

8 T. Bell, Ferritic Nitrocarburizing, Met. Eng. Q., May

1976