|

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

Buffers Cavitation Breakout Effect

Almost all

High Pressure Die Casting dies experience cavitation. This often

occurs in or the near Gate area or other locations of metal flow where the

local pressure suddenly falls below the vapor pressure of the molten metal.

Since we have

processed more than 100,000 die inserts and tooling during our 28 years,

we have also seen more distress failures of this nature than anyone else in

the industry.

A paper on this

phenomena was presented at the 2010 Casting Expo in Florida. The paper

shows why cavitation occurs, and how it can be reduced and buffered.

This destructive force is just

now beginning to be acknowledged and studied by the die casting industry.

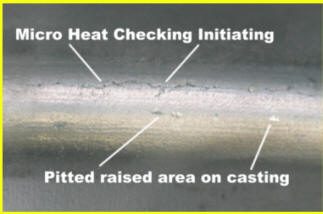

The cavitation force

and frequency is what causes these pit marks. Usually these pit marks grow

to become stress concentration points from which cracks can propagate.

Some pit marks, however, stay as pits without crack lines propagating from

them. So heat checking can occur with of without these pits.

From our experience and observation, far too often the two go together.

These pit marks in

the die steel show up as round raised rough areas on castings. People

that have been in die casting for years, mistakenly still attribute

exacerbated heat checking (thermal fatigue) to the creation of these pit

marks.

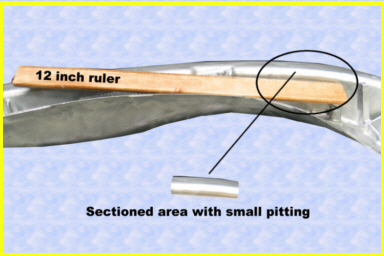

Pitting of the die causes

raised small bumps on casting

Smaller die pits, if caught early enough, can be corrected

This distress

results in higher die casting costs, either through the need for casting

rework (to remove the risers on the casting) or increased casting scrap

rates. In the worst case, repair or retirement of the die occurs.

Welding of these numerous pitted areas is not effective so many times the

dies need to be re-sunk to get below the breakout.

As

previously stated, the cavitation inception occurs when the local pressure

falls sufficiently far below the saturated vapor pressure of the liquid...a

value given by the tensile strength of the liquid.

Small low pressure vacuum

bubbles collapsing on the surface of the steel with extreme force and

rapidity create high energy "jackhammer" like shockwaves leading to steel

fatigue and breakout. Although it is hard to conceive, the vacuum

vapor in the bubble at collapse has been recorded to be 5,000 kelvin (8,540

F or 4,727 C) which is close to the surface temperature of the sun (5778

kelvin). At the same time pressures of several hundred atmospheres of

pressure (4500 psi) are exerted on the nucleating surface at the same

location with each shot.

MetaLLife

increases the

steel's fatigue strength of die steel by inducing a high value of compression

that can be as much as .018" in subsurface depth. Cracks of pits do

not start in a steel surface that is in a compressive state. Steel has

to go into tensile stress before it yields to fatigue.

This

MetaLLife

surface is textured. This surface

retains lubricant as well as changing the flow characteristics of the molten

metal. Buffering is accomplished when the bubbles collapse, not on the

steel, but on the lubricant or flowing metal that is present on the

textured surface. The buffering surface is replaced with each shot.

This integral renewable shield absorbs the implosion energy from the

collapsing bubbles which is then quickly healed with each shot.

No other die surface engineering

treatment besides

MetaLLife

and

TooLLife

can provide these two benefits.

Unfortunately

cavitation cannot be totally eliminated, however, these high energy

vacuum bubbles can be buffered. By increasing the steel fatigue

strength and causing nucleation (collapse) on another surface other than the

steel surface, the cavitation effect is buffered. Diesel engine coolant cylinder liners use the

buffering method to reduce cavitation effect to cylinder walls.

Whenever the

high velocity molten metal flow path is disrupted to cause the vapor

pressure to drop below local pressure, cavitation results. This

includes a sudden change of flow direction or obstructions to flow.

Examine your dies and see if your breakout and washout are in these areas.

To see papers, videos, and slide presentations of these forces and how they

occur in nature and the industry, visit our section.

Resources.

The

phenomenon of metal breakout is not new and

occurs in other industries besides die casting. Often it is

experienced in pumps, turbines, diesel engine cylinders and other products

such as boat propellers. The boat propeller will literally be eaten

away over time without being subjected to any type of outside abrasive or

destructive environment other than water.

Related Topics

> - Improves Metal Flow

|