|

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

Improved Casting Appearance

Flow marks or cold

shot is caused by uneven cooling of the metal and how the molten metal flows

during the casting process. When

MetaLLife

is applied to dies for casting aluminum or especially magnesium, the

resultant textured surface causes a more turbulent flow which eliminates

common flow marks. By improving flow, MetaLLife allows a more even cooling

rate of the molten metal. The flow marks may show up even after the casting

is painted or plated.

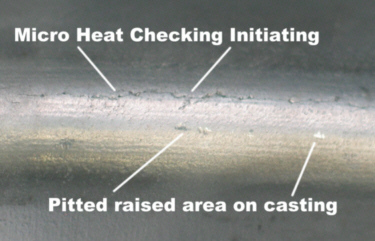

Cracks and

broken out metal in the die steel, usually do not compromise the casting

integrity. They do, however, result in a higher cosmetic reject rate

and/or frequently require extensive rework of the casting or a higher reject

rate. By being able to close up these minor cracks and by buffering

the destructive effect of cavitation breakout,

MetaLLife

helps improve overall casting appearance.

Polishing the

MetaLLife,

while it helps reveal a higher level of compression, does remove the flow

effect benefit which some customers require to obtain acceptable castings.

Rejected Casting Surface - cracking

and breakout

Related Topics >

Eliminates Laminations |