|

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

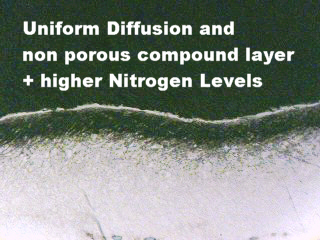

More Uniform Diffusion and Compound Layer

+

Higher Nitrogen Levels

The structure

of a diffusion zone is important. It must have uniformity with no cracks or

porosity in the compound layer. Cracking in this zone can cause

surface flaking to occur.

When

MetaLLife

is applied before

ThermaLLife,

any present porous structure is negated, plus a higher dislocation density is created

that allows more niitrogen to be diffused into the steel's surface.

The beneficial result of this is an increase in the fatigue strength of the

steel.

400x

In a recent Japanese study at Keio

University, testing was done to confirm this. The complete report is

available on our web site in the

Resource section.

Photos taken using a Scanning

Electron Microscope (SEM) show the difference between a standard nitrided and

TooLLife

like combination process surface. The photo at the right shows this comparison. The SEM

photos (a) shows cracks and pores at the surface in the niitrided compound

layer of the steel, while the

TooLLife

combination-like process (b) does not have these cracks or pores.

It was also observed in the report

that, if compressive stress (MetaLLife)

was applied before nitriding (ThermaLLife),

the amount of diffusion of Nitrogren was increased (b - below). This

concentration of diffusion zone increased the fatigue strength of the steel

over that of either process alone. This is exactly what

TooLLife

accomplishes.

Related Topics

> - Locks

compression |