|

.Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

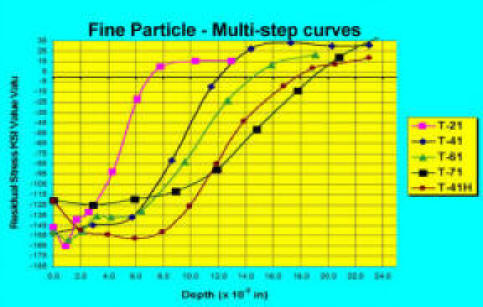

Compression Curves

Compression curves for the

various processes are shown at the right. Compression has the highest

level just below the surface. We strive to create our compression

curves with these properties in mind. Polishing can therefore be done

without losing the compressive stress benefit. Doing so, reveals the

higher level of compression. When the entire processed surface is polished,

however, the turbulent flow improvement is no longer present.

For this reason, cosmetic critical

castings are only polished, after

MetaLL ife,

in the areas where subsequent casting polishing is difficult such as in

fillets and radius/radii.

Composite

Compression Curves

show overlay of differences in each process.

How the graphed curves were plotted.

MetaLL ife

processing is monitored on a production basis by using Almen intensity

strips. These strips are placed in strategic locations on the die or

perishable tooling being processed. The Almen strip will bend upward when

processed and by measuring the height of the center curvature, the approximate

amount of induced surface compression can be determined. Various strip thicknesses

are used (C,A,N strips) dependent on the intensity of the process. i.e. For example, a

T-21 process would use a thinner Almen strip than a more aggressive

T-41H.

While the Almen strip method is useful,

it only provides a relative basis for measuring surface induced

compression. Surface compression is important, but the depth and shape of

the curve is what ultimately determines how well the process variables are being

applied. The only accurate means for determining this residual stress

distribution, is by measuring the surface and subsurface

distribution of the compression.

X-ray diffraction (XRD) is the most

accurate and proven method of quantifying the subsurface residual stress

distributions that develop during

MetaLL ife

or other mechanical compression processing. These XRD methods use

known standards established by ASTM and SAE associations. Prior to

taking these measurements exacting

criteria and

specifications for processing methods have to be established and

implemented. These specifications are applied to multiple coupon samples

which are then used in the XRD measurement phase.

Subsurface readings are then determined

by successive combination measurements using x-ray diffraction instruments and

then electro-polishing the surface to remove layers of material.

Electro-polishing removes material without inducing or changing the residual

stress values. This method is costly and destructive in nature so it

often is skipped by other competitive companies because it involves the removal of

the specimen coupon from the diffractometer each time to perform the

electro-polishing. This increases the amount of time required to take the

readings which is very labor intensive.

Badger uses X-ray diffraction for

quantifying residual stress distribution. The equipment allows the residual

stress in a coupon specimen to be measured. Layers of

material are electrochemically removed from the specimen. The resulting

residual stress layer is defined and recorded by a computer. All the

data obtained is properly corrected based on the penetration of the X-ray

beam and the amount of layer removal. By connecting the resulting data

points it is possible to accurately draw curves showing both surface and

subsurface compressive residual stress values.

Specifications - Compression and Surface

|

Compressive values (fatigue

resistance) |

|

46-48 Rc H-13 material - oil quenched coupons |

|

Max compressive value |

|

Max compressive depth |

|

Process |

Ksi

rounded |

MPa |

|

Process |

Inches |

mm |

|

T-21 |

150 |

1034 |

|

T-21 |

.006 |

0.1524 |

|

T-31 |

152 |

1048 |

|

T-31 |

.009 |

0.2286 |

|

T-41 |

155 |

1069 |

|

T-41 |

.012 |

0.3048 |

|

T-40 |

155 |

1069 |

|

T-40 |

.012 |

0.3048 |

|

T-41H |

160 |

1103 |

|

T-41H |

.018 |

0.4572 |

|

T-40H |

160 |

1103 |

|

T-40H |

.018 |

0.4572 |

|

T-60 |

150 |

1034 |

|

T-60 |

.014 |

0.3556 |

|

T-61 |

150 |

1034 |

|

T-61 |

.014 |

0.3556 |

|

T-70 |

125 |

862 |

|

T-70 |

.019 |

0.4826 |

|

T-71 |

125 |

862 |

|

T-71 |

.019 |

0.4826 |

Related Topics

> - Cosmetics |

Click for larger view

T-41H - High compression & maximized depth

More topography than T-41 depth

Applications - Heat checked - some breakout

PREFERRED BY MOST CUSTOMERS

T-41 - Good compression and depth

Applications - Heat checked - small breakout

T-21 - Compression but

not as much depth

Application - Core Pins , and Dies

Access limited - small radii or Zinc Dies

T-61 - High surface compression

(limited to flat surfaces and large radii))

T-71 - High surface compression and depth

(limited to flat surfaces with no

radii)

|