| |

|

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

Customer Testimonials

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

Letters - Over 100,000 dies processed

since 1983.

Our testimonial letters are coded

to protect our clients security)

Specific 20 year endorsement of

MetaLLife Specific 20 year endorsement of

MetaLLife

Dramatic Improvement in Tool Life

(#670 3/07/09) Dramatic Improvement in Tool Life

(#670 3/07/09)

Less

sticking soldering and drag of die casting Less

sticking soldering and drag of die casting

Improved

magnesium flow Improved

magnesium flow

Reduced

buffing and polishing time of casting Reduced

buffing and polishing time of casting

Reduced

die casting pressure - testimonial letter Reduced

die casting pressure - testimonial letter

Field Result

Comments - Preceding # is internal ref number for

customer.

(Our customer comments are

coded to protect our clients security)

Improved

performance and extended life Improved

performance and extended life

Die

casting dies for brass Die

casting dies for brass

Die casting Bronwite brass (NEW #670 03/2009) Die casting Bronwite brass (NEW #670 03/2009)

Crack

closure and prevention Crack

closure and prevention

Soldering problems resolved or reduced Soldering problems resolved or reduced

Reduction in gate erosion Reduction in gate erosion

Better Paint Adhesion Better Paint Adhesion

Reduction in porosity problems Reduction in porosity problems

Drawing field tests Drawing field tests

Blanking and cutting tools Blanking and cutting tools

20 year endorsement of

MetaLLife

#882 - WI - I have been a satisfied customer of Badger Metal Tech

for nearly 20 years.

MetaLLife

consistently delivers on its promise to substantially improve tool life in

zinc, aluminum and magnesium die cast dies. In brass die cast tooling,

regular use of

MetaLLife

coupled with proper tool steel selection/application and heat treat process

increased tool life EXPONENTIALLY!

Jerry and his Badger Metal Tech, Inc. staff are extremely helpful and always

available for any type of support needed.

MetaLLife

works because it's principle is founded on solid physics and metallugical

facts.

Thank you Badger

Metal,

Greg Flint, P.E.

Return to top

Significant improvement in tool life and die performance

#670 -

CA - In the middle 90's we were producing thin wall castings from 380.1 aluminum

alloy for Vendo - a vending machine manufacture - running over 520k parts per

year on two (2) cavity die cast dies. One die produced a gage bar and the

other produced a gate. Before we started a

MetaLLife

maintenance program with Badger Metal we were averaging 180k shots. After these

the dies were replace due to heat checking. The replacement costs for each

die was $30,000.

After approval by the customer, new dies were built and then immediately after

sampling received

MetaLLife.

This was done, as recommended by Badger Metal again at 75k and every 100k shots

thereafter for the life of the tool. We then cast 420k shots on each die

before replacing the cavities. Casting quality was improved with far

less scrap/re-melt required.

#670 - CA - The success

encouraged us to try on an eight cavity die for a brass (Bronwite C99750 alloy)

to cast Weather-Tec impact sprinklers for the irrigation industry. This is a

brass alloy that has 60% copper and 18% manganese with a melting point at 1550

degrees. Each part

weighs about .20 lbs. Prior, we could expect 100,000 shots

before die replaced. We have been using the

MetaLLife

process on these dies now for over 15 years and average 200k shots on the

tooling before replacing the cavities. Lamar tool and die casting has

other customers that request that we apply MetaLLife

to there tooling with great improvements in die life.

Badger's service is

outstanding. They are well aware of the small window regarding turn around

that is needed to meet production schedules. We continue in 2009 to use

their services with a high degree of confidence.

Larry Snoreen - Owner and

General Manager

Return to top

Less sticking, soldering, and drag

#481 - AR - Very pleased with performance of tooling for parking meters that

we did for him. Dies no longer stick, solder, or drag. Also noticed that the

heat checking on the older tools is considerably reduced with much better

casting appearance. Flow is also improved. Plans on continuing to send us

tooling as soon as production schedules free up. So impressed were they that he

sent us a LETTER praising our process and service received. Quoted as follows:

"We have recently procured the services of Badger Metal to do

maintenance work on three (3) of our dies. Most specifically, the cleaning of

these dies and the

MetaLLife

process provided by Badger. I would like to take this opportunity to express the

highest of praise to Badger Metal for the excellent services and outstanding

quality of workmanship they provided to #481 Incorporated. Turn around time

between shipment for maintenance on the dies until the time they were resumed to

us, finished; was swift and very much appreciated by all concerned (our need to

have these dies in-house is always a concern).

I was very impressed as well as 100% satisfied with every aspect of the services

that we received from Badger. I look forward to our future business dealings

with Jerry and would highly recommend Badgers' services to any potentially

interested customer."

Charlie #481

Manufacturing Plant Manager

Return to top

Reduced Casting Pressure

#299 - MN - The customer told us that after using our process for some time

he decided to try using it on a die that was giving him fits with filling.

Besides the filling problem disappearing, there was no soldering, no cracks in

the casting, and no flashing as before. He was also able to reduce his casting

pressure by 30%. The casting also looked much better with a reduction in flow

marks. Here is the customer's follow-up letter that we received:

Dear Badger Metal:

This letter is being sent to you in regards to the results of your

MetaLLife

treatment you applied to our mold that produces bracket , part #505-297.

Enclosed:

1. One part as cast with runner and spills attached

2. One part marked B (For before

MetaLLife)

machine pressure to fill 1500 PSI.

3. One part marked A-(After

MetaLLife)

machine pressure to fill 1050 PSI.

The

MetaLLife

process has allowed us to use a much lower pressure to fill the bracket.

The mold is parted with 3 cam pulls. Lower pressure has allowed us to run this

mold 2000 shots before pulling the tool and cleaning cam slides. With the higher

pressure we could run the mold only 200 shots before pulling the tool and

cleaning flash from cam slides.

Once again,

MetaLLife

Process has enabled us to increase production on this mold and many others you

have done for us in the past. Thank you once again Badger Metal Tech, and thank

you

MetaLLife.

Sincerely,

Tom Dousette - Vice President #299

Tom went on to tell us that

the World Cup Sailing Teams now use a Shark Skin finish on the hulls of all of

their boats to increase their speed. He feels that this same type of

finish obtained from

MetaLLife

allows him to improve his casting process capabilities. We know that a

MetaLLife

surface improves the flow and reduces porosity concentration. We have not,

however, investigated how reduced die pressures would assist in even further

increases in tool life. Not as yet we haven't.....

Return to top

#25 - KY - After seeing immediate improvement in the performance of a large

magnesium die casting die and its flow characteristics, this firm sent by fax

the following comments thanking us for a job well done:

Dear Mr. Skoff,

"I would like to congratulate you and your entire staff for a job well done. The

dedication to completing the work on the instrument panel cavities on such short

notice have proven Badger to be a "World Class Supplier". Thank you for your

efforts."

Sincerely,

Dave #25

Tool Engineer

Return

to top

Less sticking, soldering, and drag

#481 - AR - Very pleased with performance of tooling for parking meters that

we did for him. Dies no longer stick, solder, or drag. Also noticed that the

heat checking on the older tools is considerably reduced with much better

casting appearance. Flow is also improved. Plans on continuing to send us

tooling as soon as production schedules free up. So impressed were they that he

sent us a LETTER praising our process and service received. Quoted as follows:

"We have recently procured the services of Badger Metal to do

maintenance work on three (3) of our dies. Most specifically, the cleaning of

these dies and the

MetaLLife

process provided by Badger. I would like to take this opportunity to express the

highest of praise to Badger Metal for the excellent services and outstanding

quality of workmanship they provided to #481 Incorporated. Turn around time

between shipment for maintenance on the dies until the time they were resumed to

us, finished; was swift and very much appreciated by all concerned (our need to

have these dies in-house is always a concern).

I was very impressed as well as 100% satisfied with every aspect of the services

that we received from Badger. I look forward to our future business dealings

with Jerry and would highly recommend Badgers' services to any potentially

interested customer."

Charlie #481

Manufacturing Plant Manager

Return to top

#25 - KY - After seeing immediate improvement in the performance of a large

magnesium die casting die and its flow characteristics, this firm sent by fax

the following comments thanking us for a job well done:

Dear Mr. Skoff,

"I would like to congratulate you and your entire staff for a job well done. The

dedication to completing the work on the instrument panel cavities on such short

notice have proven Badger to be a "World Class Supplier". Thank you for your

efforts."

Sincerely,

Dave #25

Tool Engineer

Return

to top

Improved magnesium and aluminum

metal flow

#31 - IL - A

problem of flow due to the configuration of the casting and tool was preventing

good fill. The problem was eliminated after topography modification with a

special

MetaLLife

process.

Return to top

Reduced time of buffing operations

#0857 - IA -

Received via email

Paul,

MetaLLife

has been an excellent answer for us. It has eliminated many buffing

operations, and increased my die life. Thanks for all your help. Early

this summer you will see more new cavities.

Erik Hansen #0857

V.P. Manufacturing

#274 - WI - After

applying

MetaLLife

to a small barber utility tool, we were notified by our polisher that the

casting was taking less time to buff due to a reduction in hidden porosity

and better casting fill and surface characteristics. The cosmetic

requirement of this tool was such that the slightest imperfection in the

surface would show after painting which was unacceptable.

MetaLLife

got rid of this concern.

Return to top

Die Casting Dies for Brass

-

#870 - CA - We use

MetaLLife

on small brass dies sprinkler head die casting dies. Successfully have

repeated the process on both NEW and USED versions of these multiple cavity

tools to stop/close existing heat checking. Continued life extension

improvement by adding this process to tooling. We and our end user sees

improved parts with less heat checking.

-

#670 - CA - Use on brass dies and see major

improvements in life and performance on these tools. Now starting to use on

Aluminum dies for same reasons.

-

#626 - FL - Dies we processed for were previously

running brass parts and had extreme amounts of heat checking. After processing,

the dies looked so good we used these same tools to run zinc parts. Appearance

of the zinc casting is quite acceptable for our product. #626 is a captive

house.

Return to top

Improved Performance & Extended Life

-

#792 - IN - At 70,000 shots after

a

MetaLLife

treatment on ejector side, and

MetaLLife

+

ThermaLLife

on the cover side, the die continues to perform and has already out lasted

the normal life cycle where they would begin to have down time for repairs and

polishing to remove solder buildup.

-

#872 - IL - This customer has

been able to increase their tool life for a sensitive automotive part ten (10x)

fold by applying followed by

ThermaLLife

after final sampling on NEW tooling.

-

#150 - MN - Dies are running extremely well,

however, before

MetaLLife

their production manager said the dies could not be used anymore and would have

to be retooled due to excessive casting leakage problems, and sticking with

soldering. Casting appearance has tremendously improved.

-

#576 - PA - We definitely helped extend the life

on the OLD bowl die. Customer and end user are pleased. Will continue to do more

tooling.

-

#569 - KY- Very pleased with the transmission die

we did (2 cavity). Said die is running and has not stuck or broke a pin.

Customer now wants to do Cav #3,4.

-

#415 - IL - Have seen significant improvement in

die performance since starting to use

MetaLLife.

We plan to use

MetaLLife

on all of his tooling in the future.

-

#691- CANADA - The die ran great. Before we did

MetaLLife,

the die was totally unusable. Afterwards, we were able to run the die

19-20hrs/day 7 days a week with no problems. The die ran so well that we got 3

weeks ahead on production requirements. Now he will look at other tooling to do.

-

#039 - AR - We have set up a schedule to do

MetaLLife

on all of their BIG runner dies every 30,000 shots. Seeing considerable benefit

to casting appearance by incorporating

MetaLLife

as a schedule maintenance procedure.

-

#590 - FL - The first scale housing (#1786) ran

much better. Castings required much less rework. Also appeared to be some

improvement in the flow characteristics.

-

#150 - MN - Customer continues to be pleased with

results of doing the cattle tagger dies. Prior to our processing these dies he

and his customer thought that new tooling might be necessary. This is no longer

the case since the dies are holding up extremely well.

-

#659 - AR- Did a zinc die that had been welded

and was not buffing out well. We did T-21 which gave them a 60Rms finish before

buffing. The parts buffed out much better than before. Customer is very

satisfied.

-

#150 - MN - said the cattle tagger die we did in

May is doing exceptionally well after 3 runs. Their customer is pleased that he

did not have to buy a new tool which was the altemative that was being

considered if he had not found

MetaLLife.

-

#704 - CA - Vendo die is running better than ever

after

MetaLLife.

Shot rate has increased from 125/hr to 130/hr. Castings look great with a low

reject rate of .05%. Considering for other high run tooling.

-

#609 - TX - The last DET 38 endbell (new die) we

did in Nov 95 has been running since Dec 95 at a rate of 1K/day and now has

about 40 weeks of run time = 200K shots on it with still no heat checking. Have

noticed vast improvement in casting appearance and flow characteristics.

Return to top

Crack Closure and Prevention

-

#032 - Toby Parks TX - New

tooling for air conditioner component casting would heat check after only 5,000

to 10,000 shots. After

MetaLLife

no heat checking in this time frame.

-

#753 - CA - The PR3 handle that he wanted to

improve appearance if possible 50%, looked so good (at least 90% improvement)

that he is going to send us an after casting that we can use in our advertising

if desired. We have made believers out of the other owners of the company. For

the future will consider

MetaLLife

instead of building new tooling.

-

#039 - AR - Primary reason for doing

MetaLLife

is to benefit from longer runs with less downtime and tool repair from heat

checking. Cost of

MetaLLife

pays for itself by this factor alone. They schedule redoing

MetaLLife

at every 30,000 shots, scheduling permitting.

-

#321 - CA - The recent chair die mold that we did

(both cover and ejector) is running much better parts with no signs of heat

checking mirrored on the part. The die shows that the cracks are closed. Very

satisfied. Sending more castings to quote.

-

#674 OH - Ran the first set of covers we did for

one week with no problems and cracks stayed closed. Also the die seemed to hold

lubricant much better. Pleased and now wants to do the ejector sides.

-

#542 - IN - says that the previous spider die

would only get about 10,000 shots before it starting to heat check all over.

Since doing

MetaLLife

to a new set of cavities, now has 30,000 with no heat checking. We processed

this too when the die was new after about 3500 shots.

-

#705 - MEXICO - The first iron sole plate dies we

did now have about 20,000 shots on them with no new heat checking. Patrick is

pleased with the performance of the tool and plans to do it again once he

reaches 50,000 shots.

-

#760 - CA - Cosmetic appearance is one of the key

selling features of their vacuum cleaners. Heat checking on the die requires

costly secondary operations.

MetaLLife

closed up the heat checks and allowed the tool to produce the necessary quality

castings which reduced the customer's secondary costs.

Return to top

Soldering using

MetaLLife

or (MetaLLife

+

ThermaLLife)

-

#704 - CA - The combination of

MetaLLife

(T-41) +

ThermaLLife

reduces or eliminates soldering problems.

Cores tested had an established history of soldering immediately after only a

few shots or while the die was being sampled. Now they are able to run over 1000

shots without any soldering or indication of breakdown of the coating. Have

processed both small (1/2" to 5/8" dia) and large (3" dia) cores with equal

success.

-

#042 - MO - The customer eliminated solder

problems on Allied Signal cores that normally would experience build-up after

only approximately 900 shots. Two sets of cores were

MetaLLife

+

CrN coated

(processed T-21 & T-41). Cores now have 15,000 shots with still no solder or

build-up. It is interesting to note that during one of the production runs that

the water was accidently shut off to the cores, however, the resulting build-up

was minor and cleaned itself when the water was turned back on and lubricant

reapplied to the die.

-

#054 - IL - Two cores were processed with

T-41

MetaLLife.

These cores would historically solder between 12,000 to 13,000 shots. These same

cores are now at 55,000 shots without any soldering. The two cores (2.75" dia x

6.2") were processed in May 1996.

-

#032 - Toby Parks TX -New tool sticking was

always a problem on CFN cores because they have a zero to 1/2 degree draft.

Would need to polish in draft to try and prevent this from occurring. After

MetaLLife

with our T-21 process, their initiation stick problems dropped from 100% to 0%.

Have since expanded use to inserts as well as more CFN cores.

-

#670 - CA - The 3500 Pelco dies are now running

after

MetaLLife

without any soldering problems. This die because of the protruding ear always

soldered. Die cast machine operators are extremely pleased with this problem

being eliminated. Same results on the Vendo Uni-Gage dies we recently did...No

more solder problems.

-

#406- Ray Meyers OH - Still using the cores we

did. Before he was having to change the cores twice per week. Now he runs about

8 weeks without touching them. He prefers the

MetaLLife

and will be sending us more heat treated ones as soon as he has some.

-

#719- CA - (ZINC) impressed with the performance

of the core pins we did. Not only did they not solder, but they also has a

condition in the die which stressed the pins but only damaged the untreated

pins. The

MetaLLife

ones did not show as much damage. Also the first 2 weeks after our pins were

installed, the die ran phenomenally well with no soldering.

-

#032 - Toby Parks TX - His customer is "tickled

pink" with our T-41 process that we did on their ejector cores. Much less

expensive than going with an acid etch according to Toby. Also running with much

less problems. Has more to send to us.

-

#710 - OH - First parts are looking good on the

small zinc "Z" fitting. Parts are not sticking as before.

-

#664- CA- The heatsink die we did for him earlier

this month is turning our much better parts. No more sticking in the fin areas.

Also pleased with the way the heat checks are closed. Casting has a much better

appearance. Appreciated our quick turn around service (Accelerated Delivery) he

requested.

-

#671 - CO - Have been using the process since

August 1990 and would not think of running any of my tooling, whether NEW or

USED, without first putting

MetaLLife

on the dies before I do any coating. Currently we use the Futura coating

(Titanium Aluminum Nitride - TiAlN).

Return to top

Reduction in Gate Erosion

-

#001- Wl - Kevin said that the

blower housing after

MetaLLife

eliminated a second operation for cleaning up the gate area which prior to

MetaLLife

posed a handling problem. Very pleased with both physical appearance of casting

and how long the improved condition has lasted. Also said that boat motor dies

are working so well that this is the first time they have not had to weld them.

Usually every 5K shots they are welding the fin area. They have done 3-4 sets of

these tools with

MetaLLife

and all are performing equally well. Try to do every 20K shots. Die performance,

life, and casting appearance has improved considerably.

-

#001 - Wl - The boat motor die that we have

repeatedly processed with

MetaLLife

has made it through a complete production run without any welding required on

the die. According to this customer, this is the first time that they have ever

been able to run this tool for a full production run without having to weld the

tool

Return to top

Reduction in Porosity Problems

-

#693- OR - Is an end user of die castings. Since

we did our gearbox lid and housing, we have noticed a tremendous improvement in

the casting appearance with less porosity and pitting problems.

-

#30 - OH - The used transmission slides we did

worked out well that they got the additional life they needed from this die

before replacing with a new tool. Now considering doing on their new tool.

Return to top

Better Paint Adhesion

Return to top

Draw Forming Field Tests

-

#91 - IL - Applied to CPM10V draw

cap. At most would get about 60K before tool would gall and have to be

polished or replaced. Applied first the

MetaLLife

process and followed this with

Balzers TiCN coating.

Micro pockets were questioned upon return to the customer with concern about

these causing more problems than they already had experienced. Customer

was assured and tool was installed and ran 4,000,000+ parts. Engineer has

since left the company and is using

MetaLLife

at his new employment facility.

-

#498 - WI - has been enjoying the

MetaLLife benefits

since the late 80’s when their toolroom manager came across an ad in a leading

trade journal. They performed a trial in 1987, on a high volume draw and pinch

trimmed part and witnessed their "parts till polish" increase from 10,000 to

80,000 pieces. John Matteson now regularly use the process on all draw

rings. When necessary, they can polish three to four times without having

to retreat their tooling using a 600 abrasive paper and light oil. For severe

applications, such as brushed #304 stainless, he uses it as a substrate

preparation for an additional TiCN coating since they know

MetaLLife

will not peel or chip.

-

#528 - Wl - Customer called back

to say that the

MetaLLife

solved his galling problems when forming 1/8" stainless. Extremely pleased with

results.

#935 - IL - Uses on D2 and CPM tooling to reduce scoring of the produced parts.

MetaLLife allows

them to run over 6000 pieces as opposed to only a few before galling and scoring

of both the die and part would occur.

-

#680 - OH - Ran complete job of

38,000 parts with no galling or build-up on die. Now in the process of redoing

all their tooling with

MetaLLife

v/s chrome plating.

-

#680 - OH - So far has run 18,000

draw parts on a die that prior to

MetaLLife

was impossible to run as little as 200-300 parts without galling up. Parts are

better than he has ever seen off this tool. Had been using chrome plating with

no success. 'Very, very, pleased." Saved him from losing us customer.

-

#669 - NJ - The set of rectangular draw dies that

will did now have run 60,000 pcs with no pick up problems of any kind. Prior to

our process, they were having problems with galling and pickup on the comers.

-

#788 - IL- Our customer is getting their best

runs ever they have ever had with the draw ring we processed for their

application.

-

#213 - OH - The lower form die we did went from

30K to 200K parts before any redress. Overall this resulted in over a 200% life

improvement.

Return to top

Blanking, Punching and Perishable Cutting Tools

-

#46 - WI - A large stamping ring

was picking up and galling after only a few strokes. After processing this

problem has disappeared except for one small area where they had inadvertently

polished the die.

MetaLLife

was reapplied to the area and the die runs without problems.

-

#099 - WI - Was having their hobs

coated. Started to have a problem with chipping of the edge when

resharpening and during use. Now enjoy all of the

MetaLLife

life extending and fatigue resistance benefits of coatings plus the added cost

saving extra of not having to recoat when the hobs need to be resharpened.

-

#922 - WI - Uses

MetaLLife on

dies for blanking automotive and water heater parts in both compound and

progressive configurations. Customer says the treated punches run about

30% longer with much less downtime. They also like how re-sharpenings can

be done without removing the improved fatigue resistant benefits.

-

#661 - NY - The worm roll dies we

did got 4600 parts before they chipped. Normally they expect around 1700-2000

pcs before chipping occurs. He also said that even the astounding 4600 piece

figure was not a fair test because the machine these were used on had bearing

problems. Had it not been for this problem the

MetaLLife

worm roll dies would have gotten even more than 4600 pcs.

-

#680 - OH - Customer has

been using the

MetaLLife process

for over 10 year on their progressive blanking and piercing tooling.

The problems they had with chipping on their punches and dies when used on

martin site material just disappeared once

MetaLLife was

tried.

-

#063 - MN -The CPM M4 and D2 punches that we have

been doing for him since 1989 are resisting fatigue edge cracking and chipping

allowing longer runs. They are using these to stamp out 303 stainless steel

parts for the medical industry. Nothing else he has tried works like the

MetaLLife

T-10 process.

Return to top

Related Topics

> - Frequently Asked

Questions |

|

|

|

DIE SURFACE ENGINEERING

PREVENT AND FIX DIE FAILURES IN DIE CASTING DIES, DRAWING FORMING STAMPING, AND PLASTIC MOLDS.

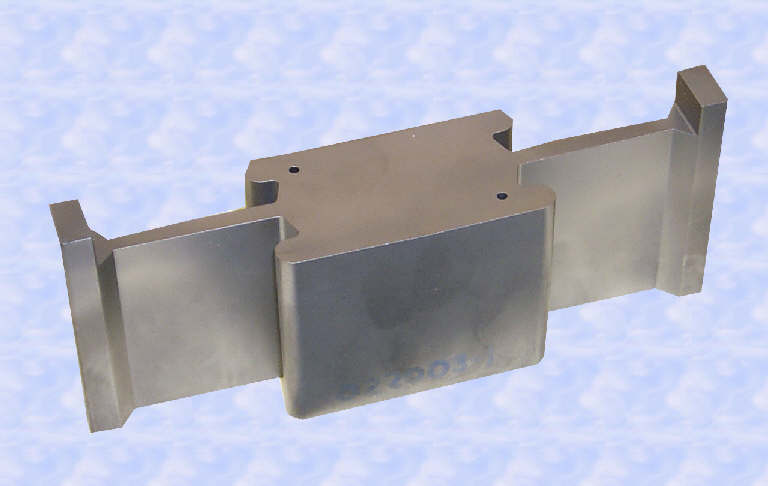

After

ThermaLLife

treatment

Send us castings to receive

Free Quotes & Consulting

within 24 hrs

|

|

|